There is no single price for a pre-engineered building. The final cost depends entirely on a set of specific factors for your project. Anyone giving a flat square-foot price without knowing your details is guessing. The price is calculated based on the specific design and materials required.

The Biggest Factor: Steel Prices

The main material in a PEB is steel. Therefore, the single largest influence on the building’s cost is the current market price of steel, both globally and locally in Pakistan. Steel prices fluctuate based on supply, demand, and raw material costs. A change in the price per ton of steel will directly impact the total cost of the building kit. This is the most volatile part of the estimate.

Building Size and Design Complexity

The physical dimensions of the building are a direct cost driver. A larger building—in length, width, and particularly eave height—requires more steel and will cost more. Design complexity also plays a major role. A simple rectangular warehouse will be more economical than a building with an unusual shape, multiple sections, or specific architectural features that require more detailed engineering and more complex steel connections.

Your Building’s Location Matters

Where the building will be constructed has a significant impact on the design and its cost. A building in an area with high wind speeds or seismic activity needs a stronger frame to handle those loads. A location that gets heavy rainfall may require a specific roof slope or drainage system. These safety and code requirements mean more steel and more engineering, which adds to the final price.

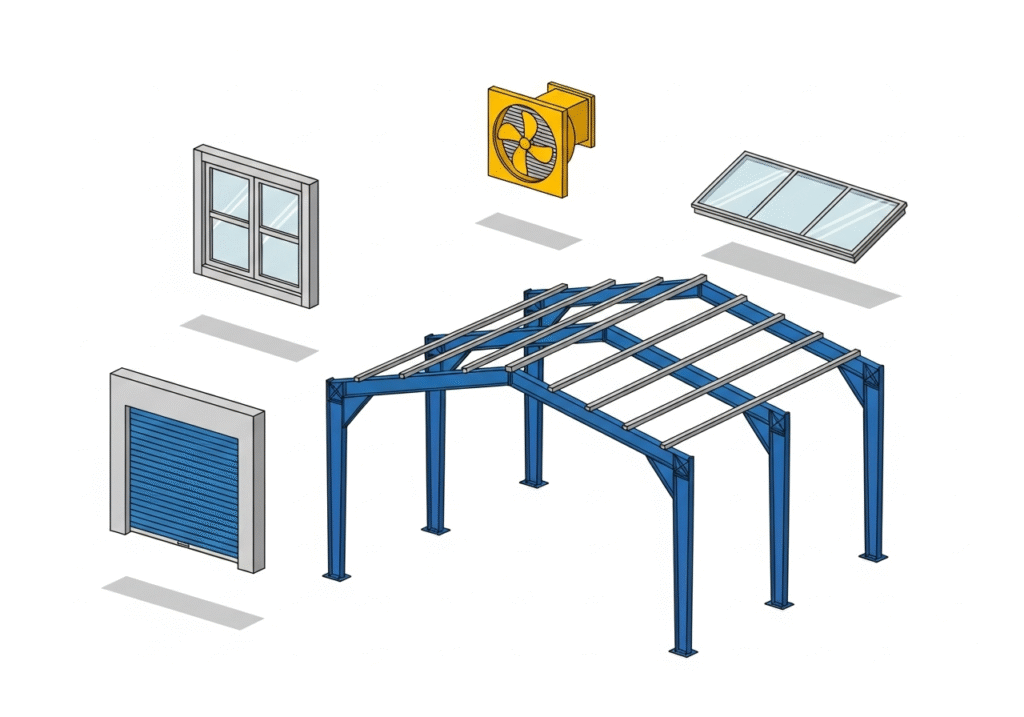

Add-ons and Accessories

The basic PEB kit includes the primary frame, secondary members, and standard cladding. Everything else is an additional cost. This includes insulation for temperature control, the number and quality of windows and doors, ventilation systems like ridge vents or louvers, and skylights. Each of these accessories adds to the material and installation cost.

Don’t Forget Foundation and Erection

A common mistake is assuming the quote for the PEB kit is the total project cost. It is not. You have two other major expenses: the concrete foundation and the on-site erection. The foundation must be engineered to support the building and local soil conditions. The cost of hiring a skilled crew to assemble the building is also a separate, significant line item.

How Poor Planning Increases Costs

Making changes to the design after the engineering phase is complete and fabrication has begun is a costly mistake. It causes delays and requires re-engineering, which adds expense. Another issue is an unprepared site. If the erection crew arrives and the foundation is not ready or the site is not accessible, you will pay for their downtime.

Getting a True Cost

To understand the real cost, you need a detailed quote from a PEB supplier. This requires providing them with your specific building dimensions, intended use, and the exact location. An accurate quote will break down the costs for the building components, accessories, and often provide an estimate for delivery. It is the only way to get a reliable number instead of a vague guess.